SJX Jet Boat Key Features and Options

A STEP ABOVE ALL OTHERS

The SJ X is your four-wheel-drive on the water.

Our design isn't just the original that started it all, it's the best inboard tunnel hull jet boat on the market, hands down.

We're not just boat manufacturers; we're boat users. These boats came out of our necessity to get where no one had ever been. Being both avid hunters and anglers and the to desire to extend our "playground" can be seen in every boat that leaves our facility. We don't like being told what can't be done; we like proving them all wrong.

THE PROVEN DIFFERENCE

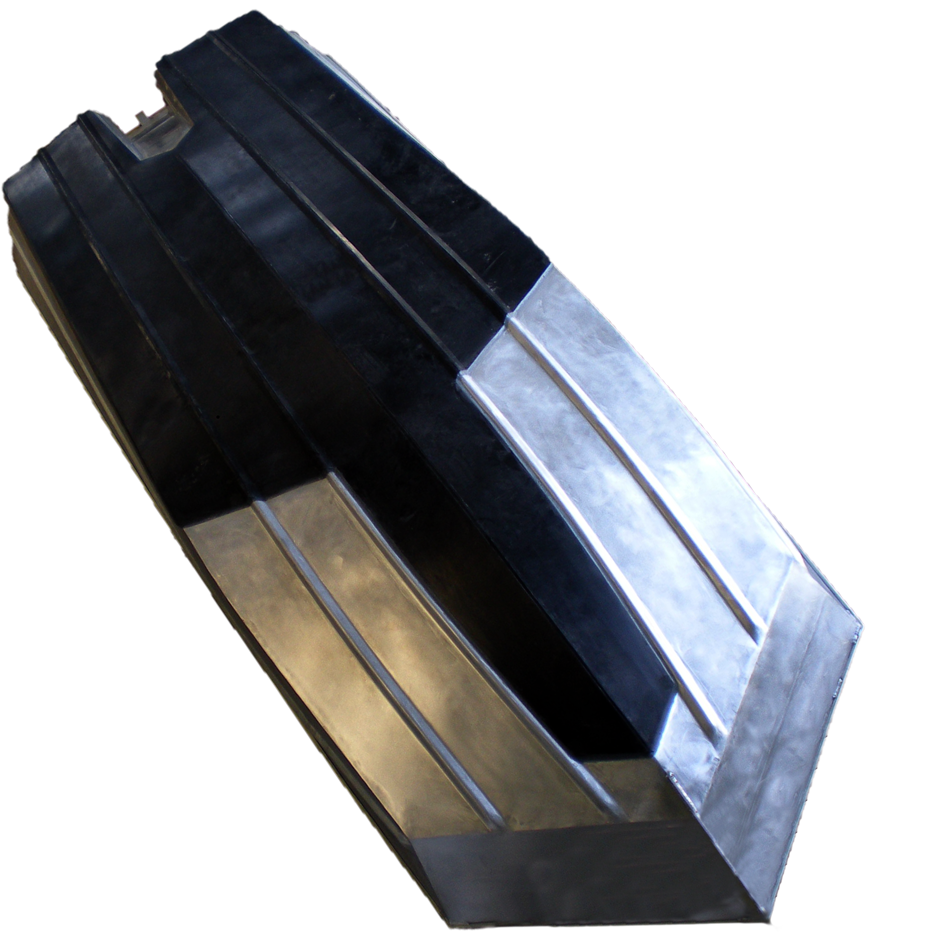

- Innovative tunnel hull design

- Mercury power plant

- A balanced power to weight ratio

- Bonded UHMW Teflon bottom

- Helm lever controlled stomp grate

- standard practice continuous welding

THE PROVEN DIFFERENCE

The biggest question we get is, "How are your jet boats able to run in such shallow water?". Well, there are a few factors that make this possible which include the frame structure of the hull along with the continuous welding we do and the balance of our power to weight ratio we have achieved, but the most significant reason would have to be the design and creation of the inboard tunnel hull.

The tunnel hull allows the jet to be elevated off the planing surface of the boat. So what this means is the jet is approximately 3 inches higher than the actual bottom of the boat. Here's what happens; as the jet boat is being pushed forward under power water from the front (where the tunnel begins) allows the water coming off the bottom surface of the boat to draw into the approach upward into the jet that is elevated off of the bottom. So in a sense, you can be hitting debris and obstacles with the bottom planing surface of the boat, but, as long as there is water, it will continue drawing up into the tunnel approach which still feeds the jet, again, because it is elevated 3 inches above. So lets say you are in a scenario where there's literally 1 inch of water, and you didn't have a choice but to go over that water, the hull, which would actually be making contact with the bottom of the river, and as long as you still have 1 inch of water, the tunnel hull is still going to draw water and then feed the jet even though you're rubbing the bottom of the river. Obviously, as result of rubbing the bottom of the river, you're stirring up the bottom and making gravel and debris loosen up which could be drawn to the pump. That's where the stomp grate comes into play and doesn't allow the bigger debris to flow into the pump or be sucked into the pump. As long as there's water being provided to the jet, you will be propelled forward. Without the tunnel hall and the jet being elevated the jet would be making direct contact to the bottom of the river at the same level of the bottom of your boat which would be in essence shoveling rocks and debris right into the jet. That's the tunnel hull difference.

UHMW TEFLON BOTTOM

Our UHMW Teflon "non-stick" boat bottom is unmatched. We took it one step further with the SJX with the addition of the UHMW Teflon bottom. The idea evolved through years of testing, trying different products on the bottom of the boat that didn't meet our standards.

The black Ice UHMW bottom

We tried paintable; we tried spray on bottoms, putting plastics on the bottom, then we came across this product that was produced in Germany. It was a bondable UHMW. We then had to come up with adhesives to bond the UHMW to aluminum, and that took the SJX to the next level. Adding Teflon on the bottom of our already incredible shallow running jet boat.

The point-n-shoot UHMW bottom

The purpose of the UHMW bottom is to give you an "insurance policy" on the bottom of your boat. When you don't see that rock that's an inch under the water when, when you don't see that stump, or that log, basically what you are doing is putting this half inch thickness insurance policy on the bottom of your boat that is slippery, durable, and takes the impact so you can hit the debris and obstacles and save your boat.

-

Woody Smith Ford

535 S. Yellowstone Highway

Rexburg, ID 83440

- Sales: 208-356-3636